AUTOMATIC TRAY LOADERS

What is it for?

The automatic loader enables standard trays to be loaded sideways onto one or two constant level trolleys. It can be installed at the exit of a tray conveyor or at the exit of a tray washer.

In particular, this enables trays to be loaded in the right direction for tray distribution systems (TURBOSELF and ARD).

Technical features

Electronic speed variator

Detection of trolley presence and full trolley

Sound and light alarm to indicate trolley change

Compatible with VALIDEX, TURBOSELF and ARD trolleys

Adjustable height

Easy operation

No more handling

Time saving

1 trolley

Technical details:

PVC rollers with stainless steel axles and ball bearings for transferring trays onto the trolley

Inclination of connecting element to fit tray washer or conveyor

2 trolleys

Technical details:

PVC rollers with stainless steel axles and ball bearings for transferring trays onto the trolley

Inclination of connecting element to fit tray washer or conveyor

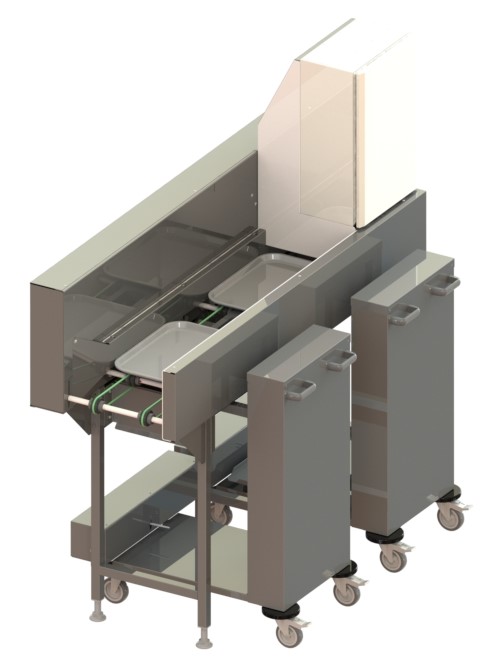

Robotic tray destacker

Robotic system for unstacking trays from a constant-level trolley onto a conveyor. Our solution can be used with dirty trays to be loaded into a tray washer. Operation is autonomous after cycle start, which saves time for operators. The equipment operates without pneumatic energy and requires only a power supply.

Technical features

- Stainless steel frame and cowling

- Space dedicated to the introduction of a constant-level trolley

- Tray gripping by suction

- Tray movement by 2-axis robot

- Cord conveyor for introduction into the tray washer

- Can be adapted for non-VALIDEX constant-level trolleys

- Space-saving design